A photo of a lignite (a type of coal) excavator that runs on electricity has been shared several thousand times on Facebook since early September by netizens falsely claiming that it mines lithium and “consumes 450 liters of fuel in 12 hours”. The text shared on social networks, which intends to denounce the environmental impact of the extraction of lithium intended for the batteries of electric cars, also multiplies the approximations, explained several experts to AFP.

A photo, shared more than 23,000 times on Facebook since September 4, 2022, shows a huge machine with a bucket wheel. “This machine must move 500 tons of earth/mineral to be refined to create a lithium car battery. Consumes 450 liters of fuel in 12 hours of work”, comments the Swiss author of this publication.

The rest of the text contains several figures intended to denounce the impact of lithium extraction on the environment: “A lithium mine is estimated at 75 loads of sulfuric acid per day”, affirms the author of the text, which also assures that “according to the estimates of Lithium Americas which (sic) quotes the New York Times, a mine will consume 12,200 liters of water per second to produce 66,000 tons of lithium carbonate per year”. The author also describes the composition of a Tesla brand battery and concludes that “manufacturing an electric car pollutes 70% more than a gasoline car”.

Lithium is a light metal found mainly in Australia, Argentina, Chile, Zimbabwe and China. Used for storing energy in telephone and computer batteries, it has also become an essential resource for the energy transition with the rise of electric cars.

Its extraction does indeed have a significant impact on the environment, as the text shared by Internet users suggests: it may require the extraction of large quantities of rocks and the use of very large volumes of water.

However, this text contains untruths and many approximations. Thus, the photo on which he relies does not show a lithium excavator, but lignite. The latter does not run on fuel, but on electricity. Moreover, the mine of the Canadian company Lithium Americas mentioned does not consume 12,200 liters of water per second, but per minute. As for the weight and composition of electric car batteries, they vary.

A lignite excavator that runs on electricity

In the comments under the post, several netizens report that the photo does not show a machine used to extract lithium from rock, as claimed in the misleading post, but an electric coal digger. Some even cite a specific excavator model, the Bagger 288.

A reverse image search – see here how to do it – from the photo published on Facebook also makes it possible to find several sites and forums, like this one, sharing the same photo with “Bagger 288” in the caption. The Bagger 288 is one of the largest land vehicles in the world: as heavy as 8,600 cars, it is as tall as the Statue of Liberty, explains the site of its manufacturer, the German steel group Thyssenkrupp, on which we also find the photo shared in the misleading publication.

The site also indicates that the Bagger 288 is used in the Garzweiler mine in western Germany, which mines lignite – a type of coal. Several media, including AFP, the Huffington Post or La Tribune, have mentioned this coal mine in articles recounting demonstrations against the extension of the Garzweiler mine, which threatens a village near the site.

The Thyssenkrupp Group confirmed by email to AFP on September 15, 2022 that the photo shows the Bagger 288 excavator.

AFP also contacted the owner of the Garzweiler mine, the German group RWE. A spokesman, Guido Steffen, said by email that “the Bagger 288 was built at the Hambach mine and was used for the first time there”, before being moved to the Garzweiler mine. in 2001.

“We have six excavators of this size, capacity and shape, therefore capable of extracting up to 240,000 tonnes per day,” added Guido Steffen. “They were built by the two industrial groups Krupp and MAN/Takraf. With the exception of No. 288, they are all located and operational in the Hambach mine”, another coal mine located south of that of Garzweiler.

Guido Steffen clarified that these six excavators, including Bagger number 288, “run on electricity”.

Contrary to what the author of the text we are checking claims, this machine does not extract lithium. It also does not consume “450 liters of fuel in 12 hours of work”, since it is electric.

The figure of 500 tonnes of earth to move for a single lithium battery is “exaggerated”

“This machine must move 500 tons of earth / mineral to be refined to create a lithium car battery”, writes the author of the publication.

The AFP has already looked into a similar assertion in two previous articles, in English and in German, which checked publications evoking “227 tons of earth” necessary for the manufacture of an electric battery.

Jens Buchgeister, a member of the research group “Research for Sustainable Energy Technologies” at the Karlsruhe Institute of Technology, explained to AFP in May 2022 that it is not possible to state precisely how much soil excavation required. “The mined ores contain several metallic raw materials as well as other valuable raw materials mined together and made available, through different processes, in their specific fields of application.” In other words, multiple minerals can be extracted from the same rock and then separated for different uses, as the French government’s Minéral info site also explains.

Asked about this topic, Peter Newman, professor of sustainability at Australia’s University of Curtin, also said in May that “it is difficult to determine how much earth is moved during the mining process. Factors such as geography, type, feedstock concentration and recovery rates all impact results,” he explained.

In another AFP article, Patrick d’Hugues, director of the Mineral Resources and Circular Economy program at the Bureau of Geological and Mining Research (BRGM), explained that “there is not a figure, there are figures. Depending on the number of batteries, and their quality and weight, we will have a whole range of figures. Taking a figure like that is always a bit doubtful”, he declared in September 2021, adding that the figure of 225 tons of raw materials to manufacture an electric car battery “is extremely exaggerated”.

For Karine Samuel, university professor expert in risk management in supply chains at the University of Grenoble Alpes, interviewed in September 2021 by AFP, “the figure of 225 tonnes of raw material does not really make sense. To obtain the metals used in the batteries of electric vehicles, there are different more or less sensitive steps, and we cannot approach this in a global way.”

Batteries with variable composition and weight

In the post we are checking, the text lists the components of an “electric car battery, say a Tesla”, to the nearest kilo. However, the weight and composition of electric car batteries vary from one vehicle model to another.

As this AFP dispatch published in September 2020 explains, the majority of rechargeable batteries for electric cars today work with lithium-ion cells. This type of battery is composed of lithium, cobalt and often nickel on its positive electrode, and graphite on its negative electrode. Between the two, there is liquid lithium where the electrons circulate. The movement will cause an electrical reaction to operate a device or recharge it.

The author of the Facebook post assumes that all electric car batteries would be so-called NMC batteries, including nickel, manganese and cobalt, which he cites in his text. However, the American manufacturer Tesla has decided to produce around half of its cars with LFP batteries, said Marko Paakkinen, research team leader at the VTT Technical Research Center of Finland, interviewed on March 22, 2022: “They use lithium, iron and phosphate as critical raw materials, and are therefore more environmentally friendly than NMC”.

The rare metals contained in the batteries play an essential role. Very powerful, they make it possible to limit the size of the batteries, and represent a significant part of their weight. “An electric car battery is made up of about 160 kilos of metals, including a large part of graphite, aluminum and nickel, sometimes lithium and others still”, according to Karine Samuel.

The battery used for the Tesla Roadster model, an electric sports car, weighs between 400 and 450 kilos, as explained on the Tesla company website. But other batteries are lighter, like that of the Renault Zoé at 326 kilos, the Mitsubishi i-MiEV at 200 kilos, or the Fiat 500 at 186 kilos. But there are also heavier models, such as the Audi e-Tron with its 700 kilo battery.

Approximations on lithium extraction techniques

There are two main ways to extract lithium, explains Eric Pirard, professor at the University of Liège and expert in mineral resources and circular economy.

The first consists in the extraction of lithium from igneous rocks. “To dissolve the lithium, you have to dissolve the mineral in these rocks”, explained Eric Pirard on September 14, 2022 to AFP. “So far, we haven’t found anything better than acid” for this process, called “leaching” and described in this video.

The author of the text we are checking writes that a lithium mine is estimated at 75 charges of sulfuric acid per day”, a unit which means “nothing” according to Eric Pirard, who indicated that “one must count 64,000 tons of sulfuric acid to process 200,000 tons of spodumene concentrate – a type of lithium mineral – and produce 41,000 tons of LiOH (lithium hydroxide)”.

This technique is the one chosen by the Canadian group Lithium Americas for its mine project in Nevada. This mine, intended to power a million electric cars, is the subject of strong opposition from certain residents and associations, who have started a legal battle in federal court to block this project.

As this article in Le Monde explains, the inhabitants are worried about sulfuric acid discharges, in this region where rare species live, but also about the construction of an industrial zone in the desert and the scarcity of water, essential for breeding.

Lithium mines indeed require a large quantity of water, which also risks being polluted by poorly controlled releases of chemicals, as explained by CNRS researchers. The NGO Amnesty International also warns that “the growing demand for ‘green’ batteries brings new risks to the environment, including pollution of mining areas, damage to the seabed, and the accumulation of waste due to to an ineffective design”.

“According to estimates by Lithium Americas which (sic) quotes the New York Times, a mine will consume 12,200 liters of water per second to produce 66,000 tons of lithium carbonate per year,” says the author of the publication that we let’s check.

It appears to refer to a New York Times article published on May 6, 2021 titled “The Lithium Gold Rush: In the Race for Electric Vehicles”. The figures quoted by the NYT, which cites the company, are actually 3,224 US gallons (or 12,200 liters of water) per minute, not per second.

The second process for recovering lithium is the extraction of this metal from brines – water loaded with dissolved solid elements, therefore saturated with salt, which is evaporated in order to extract the mineral, “a a bit like salt marshes”, commented Eric Pirard.

In Germany, the Australian company Vulcan Energy is developing one of the main European lithium extraction projects, designed to be more energy efficient and less polluting.

The impact of the electric car on the environment

“In general, it is clear that the massive development of the electric automobile will require enormous quantities of Li (lithium, editor’s note), but also of copper, cobalt, manganese, nickel, aluminum… Including the massive extraction will have a very significant energy cost and environmental impact”, commented Nathalie Job, materials and process engineer for energy transformation and storage at the University of Liège, interviewed on September 14, 2022.

“At the beginning, we may have tried to make people believe that it was a car with no impact on the environment. It was oversold as the miracle solution. But it is a car that also has an impact on the environment. the environment. But when you look globally and compare to thermal vehicles, the electric car still has certain environmental benefits”, declared Patrick d’Hugues, from BRGM, in September 2021.

On its website, the NGO International Council for Clean Transport (ICCT) explains that the greenhouse gas emissions linked to the production of a lithium battery “vary between 65 and 100 kilograms of CO2 equivalent per kWh of battery capacity, depending on whether the battery is produced with electricity from the relatively clean European grid, the United States or the coal-intensive Chinese grid (…) In other words, the construction of an electric vehicle battery is approximately 1.5 times more carbon intensive than a comparable conventional vehicle.The difference is attributable to emissions from the manufacture of the battery itself, including all emissions upstream of the actual manufacturing process said, such as those associated with the extraction and processing of raw materials,” the site explains.

However, nuance the NGO, the emissions of electric vehicles are lower in use than those of thermal vehicles, thanks to the decarbonization of the global electricity grid and the high efficiency of electric motors, which need much less energy. to move.

The result is that an electric vehicle “quickly recoups the higher emissions from the manufacturing phase,” concludes the ICTT.

Other studies tend to show that the overall ecological impact of the electric car, which takes into account its entire life cycle, is better than that of a thermal vehicle.

On its page devoted to checking myths around electric vehicles, the United States Environmental Protection Agency (EPA) explains that “the greenhouse gas emissions associated with an electric vehicle during its lifetime lifetimes are generally lower than those of an average gas-powered vehicle, even accounting for manufacturing.”

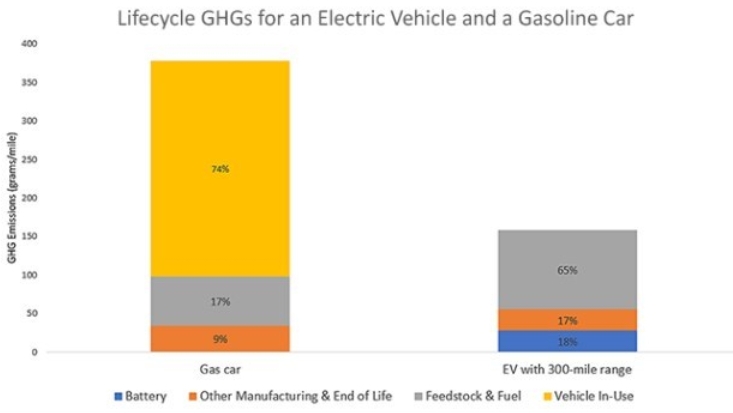

The EPA presents a diagram “for information purposes”, comparing the greenhouse gas emissions of an electric car with those of a gasoline car (in 2020). According to this diagram, “electric vehicles indeed pollute more during their manufacture and recycling, but up to 36%” and not 70% as claimed by the publication shared on Facebook, told AFP Ivan Lucas, lecturer at the Sorbonne University, interviewed on September 21, 2022. “The total balance sheet remains in favor of electric vehicles, even considering that the electricity used is not 100% carbon-free”.

Another study by the Flemish university Vrije Universiteit Brussel (VUB), conducted in 2015 with the MOBI research center and presented on the VUB website concluded that “during their lifetime, electric vehicles emit three to four times less CO2 than a diesel car, taking into account the way we produce electricity in Belgium”. The interviewed author recalls all the same that “it is however important to underline that major environmental improvements are still necessary during the extraction of raw materials in South America or China, and that the recycling of materials can further reduce environmental impact”.

“Overall”, commented Eric Pirard, “when you use a mobile phone or an electric car, you have to keep them as long as possible. If people realized the industrial effort that battery construction requires, they would not wouldn’t keep their phone for a year and a half”.

In Belgium, all company cars will have to be electric from 2026 to benefit from tax deductibility. In Flanders, individuals will have to buy an electric model from 2029.

In France, electric cars accounted for 12% of new passenger vehicle registrations in the first eight months of 2022.